New Paragraph

SERIES Q

Because customized requirements require personal advice.

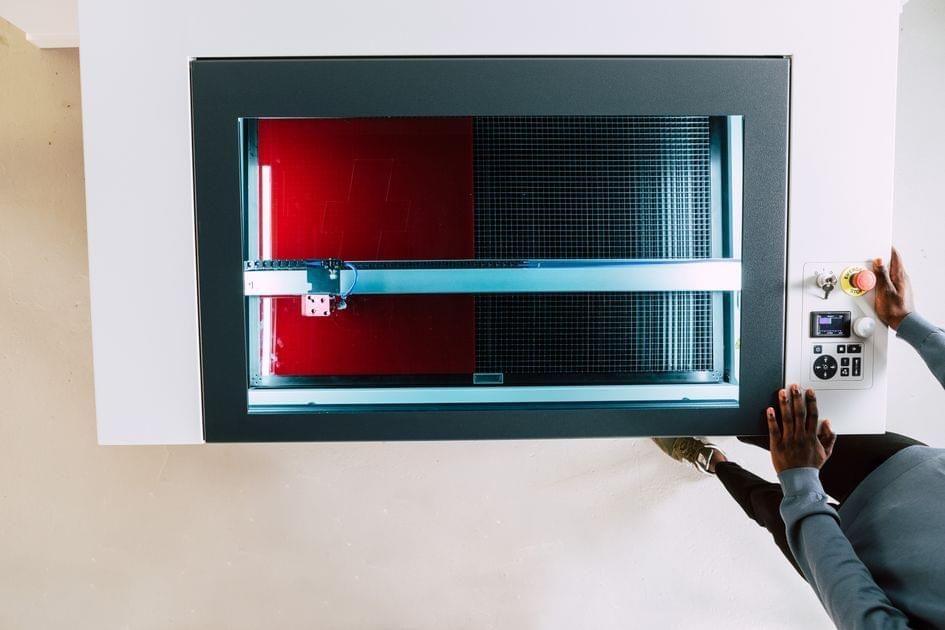

WHY YOU NEED A MID-RANGE LASER CUTTING MACHINE FROM OUR Q SERIES

The Q laser cutting machine stands for efficient cutting and the best value for money. With a working area of 1300 x 900 mm and a laser power of up to 120 W, the laser machine cuts and engraves a wide variety of materials: acrylic and wood (cutting up to 15 mm), textiles, paper and cardboard, signs, crafts, models or decorative items. The Q series has everything a laser cutting machine needs and offers reliable laser machines for production.

BECAUSE IT IS MORE EFFICIENT WITH A LASER CUTTING MACHINE

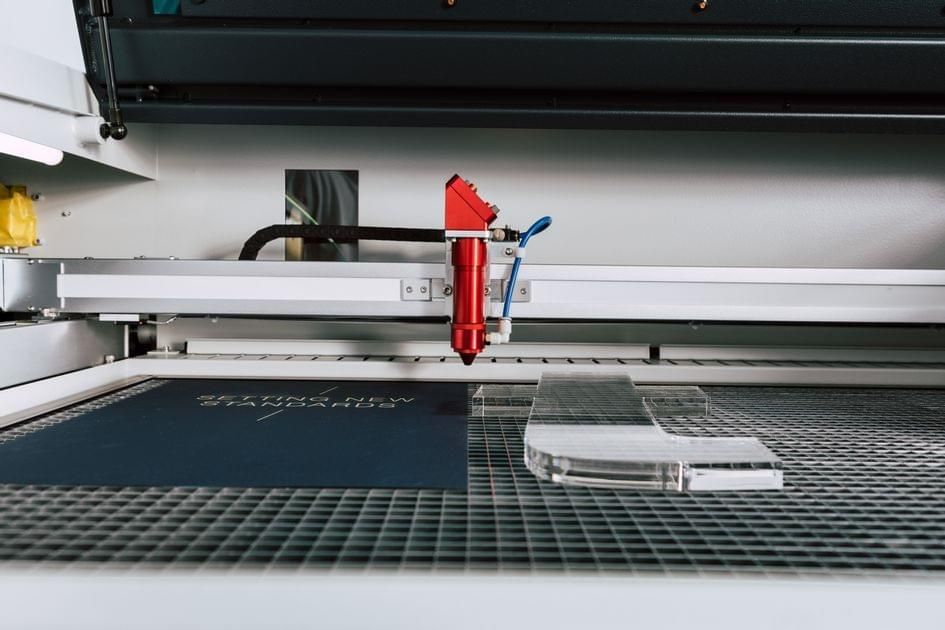

How is the productivity promise kept? Using Trotec's core technology: Drive design and OptiMotionTM provide the speed, the Trotec red laser head enables fast yet precise laser processing. The ultra-compact and lightweight design integrates the most important functions into the smallest of spaces. InPackTM technology: protects all sensitive components of the mid-range laser cutting machine from dust.

BECAUSE WITH THE LASER CUTTING MACHINE YOU CAN WORK RELIABLE AND FOR A LONG TIME

The Q500 laser cutting machine is equipped with a powerful DC CO2 laser for faster laser cutting, a CeramiCore® RF CO2 laser for high-quality laser engraving, or both. The innovative and patented CeramiCore® laser source concept stands for reliability, long life and high engraving quality. The laser source resonator, where the laser beam is generated, is 100% ceramic. One investment, two tools.

BECAUSE YOU CAN WORK INTUITIVELY WITH THE MID-RANGE LASER CUTTING MACHINE

Ruby®, the design software for your laser machine, ensures a smooth workflow. Create graphic, photo and text elements and make adjustments quickly thanks to the integrated workflow. With software that is also a graphic design software and a laser program. A user interface that inspires. Ruby® connects all your laser machines in a network.

CUT UP TO 8 TIMES FASTER

Move through curves like they’re on rails. Our unique OptiMotion™ path control automatically adapts cutting speed to the geometry of your design. Achieve the best contour accuracy with the highest cutting productivity. This is an unbeatable advantage, especially with thin materials such as foils or vector marking.

3.2 s cutting task with Q

27 s cutting task with a comparable laser

EVERYTHING YOU NEED FOR LASER CUTTING

Cut and engrave a wide variety of materials. Acrylic, wood, textiles, paper or cardboard up to 15 mm thick. The Q series combines all the Trotec virtues for efficient laser cutting - everything you need for laser cutting.

15mm maximum material thickness

>20 materials

1 INVESTMENT, 2 TOOLS

Achieve perfect results when cutting and engraving. Integrated DC CO2 laser sources for fast cutting and CeramiCore® RF CO2 for high-quality engraving.

1 laser machine

2 laser sources

MULTIPLE USERS

Work as a team with different roles and permissions. For example, operators cannot adjust laser parameters, they can only assign them. Students cannot start working with the laser without a teacher. Graphic prepress and laser production work seamlessly. Multiple users - 1 laser machine.

4 easy steps

∞ users

RECORD TWICE AS FASTER

Engraves twice as fast as basic low-cost laser machines. A sign that takes 10 minutes on a basic laser machine can be engraved in less than 5 minutes with the Q Series. 2m per second and 2G maximum engraving speed make it possible.

2x faster engraving

2G acceleration

More features of mid-range laser cutting machines.

INTUITIVE APPROACH

Focus quickly and easily at the touch of a button thanks to the SonarTechnology™ ultrasonic sensor.

MINIMAL CLEANING

Sensitive components (lenses, linear guides) are protected from dust and dirt by our InPack™ technology with integrated air purge system.

EFFECTIVE EXTRACTION SYSTEM

Less contamination of workpieces, less flame formation and a long service life of the laser machine with the right extraction system: Trotec Atmos.

SOPHISTICATED TECHNOLOGY

Reliable operation, long service life and low maintenance costs thanks to reliable Austrian mechanical engineering.

ALWAYS PRODUCTIVE

TroCare is a tailor-made service package that ensures maximum productivity and manageable operating costs.

PRINT AND CUT WORK PRODUCTION

Precise cutting of printed applications thanks to Trotec Vision.

ROTARY ENGRAVING

Engrave glasses, bottles, mugs and more with the rotary engraving attachment.

A COORDINATED SOLUTION

Support, laser machine, extraction system and material all in one: one contact person for everything.

CE SAFE

Our machines meet all official requirements and can therefore be operated safely.

PRINT AND CUT WORK PRODUCTION

Precise cutting of printed applications thanks to Trotec Vision.

Comparison of the working surfaces of our mid-range laser cutting machines.

Q Series Technical Data

| Q500 DC | Q400 DC | Q400 RF | |

|---|---|---|---|

| Work area (w x h) | 1300 mm x 900 mm | 1030 mm x 630 mm | 1030 mm x 630 mm |

| Max. height of workpiece | 45 mm | 200 mm | 200 mm |

| Cargo area (an x prf) | 1400 x 1150 mm | 1130 x 690 mm | 1130 x 690 mm |

| Dimensions (W x H x D) | 1870 x 1655 x 1110 mm | 1550 x 1080 x 1080 mm | 1550 x 1080 x 1080 mm |

| Max working speed | 2 m/s | 2 m/s | 2 m/s |

| Max acceleration | 15 m/s² | 15 m/s² | 15 m/s² |

| Motion system technology | Servomotors | Servomotors | Servomotors |

| Laser power | Sealed CO2 laser DC 120 W | Sealed CO2 DC laser 100 W | Sealed CO2 RF laser 60 W |

| Laser Safety | CDRH laser safety, laser class 2, CE compliant, double safety locking system, emergency switch and key | CDRH laser safety, laser class 2, CE compliant, double safety locking system, emergency switch and key | CDRH laser safety, laser class 2, CE compliant, double safety locking system, emergency switch and key |

| Weight | Aprox. 570 kg | Aprox. 300 kg | Aprox. 300 kg |

| Energy consumption | 100V - 250V, 1100 - 1500 W | 100V - 250V, 1200 W | 100V - 250V, 1200 W |

| Cooling system power consumption | 900 W | 900 W | 900 W |

| Refrigeration system | Water cooled | Water cooled | Water cooled |

Materials compatible with the Q series

| Grabar | Cut | |

|---|---|---|

| Acrylic | ✔ | ✔ |

| Glass | ✔ | |

| Plastic sheets | ✔ | ✔ |

| Leather | ✔ | ✔ |

| Paper | ✔ | ✔ |

| Plastics | ✔ | ✔ |

| Stone | ✔ | |

| Textiles | ✔ | ✔ |

| Wood | ✔ | ✔ |

DOWNLOAD FILES

Frequently Asked Questions about Machines

mid-range laser cutting.

What is the best laser cutting machine for my project?

Q Series laser cutting machines are suitable for anyone looking to cut a variety of materials. Safety, reliability and ease of use ensure high productivity in daily laser activity. With CE compliance, servo motors and RF or DC laser power up to 120W, Q Series laser cutting machines are perfect for your project.

What is the best laser cutting machine for beginners?

For beginners, we recommend the Q-series laser cutting machines. The simple operation of the laser cutting machine, as easy as printing, allows for a quick and trouble-free introduction to laser technology. The material database supports beginners with the endless possibilities for material selection, and the intuitive operation makes working with the laser machine a real pleasure.

How much does a laser cutting machine cost?

The purchase price of laser equipment depends on its configuration and needs. Costs may vary depending on the work surface and laser power. At CeluPal International we can advise you when choosing the right laser equipment for your needs.

Because customized requirements require personal advice.

LOCATION

ADDRESS

3rd Street 53, Naucalpan Industrial Park, Naucalpan de Juarez

PHONE

52 (55) 2625 2990 / 01 800 000 CEL (2358)E

SCHEDULES

Monday to Friday from 9:00 a.m. to 6:00 p.m.

© 2024 Celupal All Rights Reserved