SPEEDY SERIES

Because customized requirements require personal advice.

WHY YOU NEED A SPEEDY LASER ENGRAVING AND CUTTING MACHINE

Whether you are just starting your business or looking to increase your production capacity, Speedy is the perfect choice. As the fastest laser engraver on the market, Speedy will help you make your daily business profitable. Premium components and reliable mechanical engineering ensure minimal maintenance and maximum uptime. Ruby®, the most intelligent laser software, ensures a smooth workflow from initial idea to finished product.

INCREASE YOUR PRODUCTIVITY WITH A SPEEDY LASER ENGRAVER

Time is money – time per laser job is crucial to the success of your business. Engraving speed of 4.3 m/s and 5 g, OptiMotionTM motion control and laser power of up to 120 watts make the Speedy not only the fastest but also the most productive laser engraving and cutting machine on the market.

MORE FLEXIBILITY WITH THE SPEEDY LASER ENGRAVER

Discover endless application possibilities thanks to the CO2 and fiber laser in a single machine. With the Speedy you can perform any CO2 laser application, as well as marking tasks by annealing or engraving metals.

The patented flexxTM technology, the multifunctional table concept and a variety of carefully thought-out options allow for complete flexibility.

MAKE YOUR WORK MORE EXCITING WITH THE SPEEDY LASER ENGRAVER

Ruby® laser design software ensures a smooth workflow. Create graphic, photo and text elements and make adjustments quickly thanks to the integrated workflow. With software that is also a graphic design software and a laser program. A user interface that inspires. Ruby® connects all your laser machines in a network, locally or from anywhere.

OPTIMIZE PRODUCTION WITH INTELLIGENT MONITORING

The Speedy models, together with the Atmos Pure extraction systems, seamlessly combine extraction control and laser operations via Trotec's Ruby® software. Enjoy higher application quality with integrated extraction settings and monitor filter status conveniently from Ruby®, maximising efficiency.

CUT UP TO 8 TIMES FASTER

Move through curves like they’re on rails. Our unique OptiMotion™ path control automatically adapts cutting speed to the geometry of your design. Achieve the best contour accuracy with the highest cutting productivity. This is an unbeatable advantage, especially with thin materials such as foils or vector marking.

3.2 s cutting task with Speedy

27 s cutting task with a similar laser

MAXIMUM DURABILITY AND WORK QUALITY

Achieve a uniform engraving image and cut out the most delicate details thanks to the best power stability and a fine laser pointer. Inside the Trotec laser machine, the patented CeramiCore® laser source technology has an impressive durability.

Never refill the CO2 gas of the laser and you will have to replace the laser machine less frequently, so you can use your laser machine for much longer.

≤1.2 quality mode

120µm pointer size

INFINITE OPTIONS FOR MORE PRODUCTS

Perform a multitude of different applications with flexx™ technology. CO2 and fiber lasers are integrated into one machine. This allows you to offer more laser products to your customers. You can perform direct metal marking, annealing marking or any other CO2 laser application with one machine. From wood to glass or plastic, you can process any material with just 2 mouse clicks. Fewer steps than any other laser machine on the market.

2 different laser sources

1 machine

MORE ENGRAVINGS IN LESS TIME: THE CHEAPEST LASER HOUR

Engrave faster than ever before and than anyone else. Even in small increments of up to 2 pt. Clearly legible engraving results in the shortest possible time. Trotec's drive system design, dynamic motors and sophisticated control electronics enable engraving at 4.3 m/s and 5 g, making our Speedy the fastest laser engraver on the market.

4pt fonts available

47 minutes for 1000x600mm

FOR EASIER AND FASTER WORK WITH YOUR LASER MACHINE. FULLY DIGITAL

Easily create designs, graphics, photos and text from initial idea to finished piece with Ruby®. The integrated workflow makes adjustments quick and easy. Ruby® connects all your laser machines on a network, locally or from anywhere. Jobs can be distributed across multiple machines from a PC or Mac.

4 easy steps

50% time saving

More features of laser cutting machines.

INTUITIVE APPROACH

Focus quickly and easily at the touch of a button thanks to the SonarTechnology™ ultrasonic sensor.

MINIMAL CLEANING

Sensitive components (lenses, linear guides) are protected from dust and dirt by our InPack™ technology with integrated air purge system.

EFFECTIVE EXTRACTION SYSTEM

Less contamination of workpieces, less flame formation and a long service life of the laser machine with the right extraction system: Trotec Atmos.

SOPHISTICATED TECHNOLOGY

Reliable operation, long service life and low maintenance costs thanks to reliable Austrian mechanical engineering.

ALWAYS PRODUCTIVE

TroCare is a tailor-made service package that ensures maximum productivity and manageable operating costs.

PRINT AND CUT WORK PRODUCTION

Precise cutting of printed applications thanks to Trotec Vision.

THE RIGHT WORK TABLE

High quality products and fewer defective products with the right table for every application.

A COORDINATED SOLUTION

Support, laser machine, extraction system and material all in one: one contact person for everything.

CE SAFE

Our machines meet all official requirements and can therefore be operated safely.

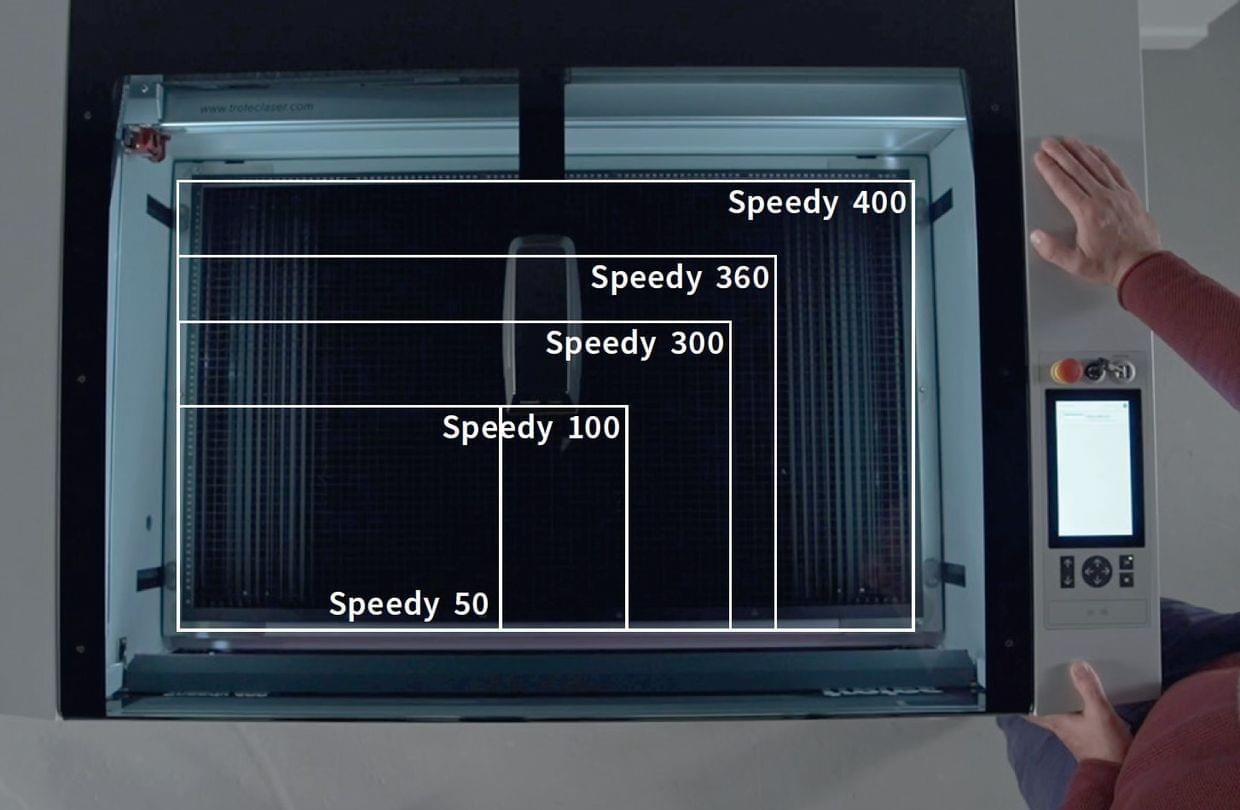

MORE SPACE IN THE WORKSHOP

The ideal ratio between machine size and work surface allows for greater flexibility and reduced space requirements.

Comparison of the working surfaces of our mid-range laser cutting machines.

Technical data of the SPEEDY series

| Speedy 400 Run on Ruby® | Speedy 360 Run on Ruby® | Speedy 300 | Speedy 100 | Speedy 50 | |

|---|---|---|---|---|---|

| Work area (w x h) | 1016 x 610 mm | 813 x 508 mm | 726 x 432 mm | 610 x 305 mm | 457 x 305 mm |

| Max. height of flexx workpiece | 305 mm | 210 mm | 200 mm | 170 mm | 141 mm |

| Cargo area (an x prf) | 1096 x 698 mm | 890 x 600 mm | 795 x 440 mm | 690 x 346 mm | 510 x 380 mm |

| Dimensions (W x H x D) flexx | 1428 x 952 x 1073 mm | 1221 x 830 x 1066 mm | 1130 x 943 x 1054 mm | 1018 x 784 x 467 mm | 726 x 447 x 672 mm |

| Max working speed | 4.32 m/s | 3.55 m/s | 3.55 m/s | 2.8 m/s | 1.5 m/s |

| Max acceleration | 50 m/s² | 50 m/s² | 50 m/s² | 40 m/s² | 35 m/s² |

| Motion system technology | Brushless DC Servo Motors | Brushless DC Servo Motors | Brushless DC Servo Motors | Brushless DC Servo Motors | Stepper motor |

| Flexx CO2 laser power | 60 - 120 W | 60 - 120 W | 60 - 120 W | 60 - 80W | 30 W |

| Flexx fiber laser power | 20 - 50 W | 20 - 50 W | 20 - 50 W | 20 - 30 W | n.d. |

| Laser class | 2 | 2 | 2 | 2 | 2 |

| Flexx weight | 100V - 250V, 1100 - 1500 W | 335 – 350 kg | 215 kg | 150 kg | 53 kg |

| Flexx energy consumption | 1~230V / 50/60Hz / 10.2 A 1~115V / 50/60Hz / 15.3 A | 1~230V / 50/60 Hz / 9.6 A 1~115V / 50/60 Hz / 14.2 A | 1 ~ AC 110-230V 50/60Hz, max. 1.4 kW 1 ~ AC 230V 50/60Hz, max. 1.8 kW (100 - 120 W) | 1 ~ AC 110-230V 50/60Hz, 1.3 kW (60 watts) | 1 ~ AC 110-230V 50/60Hz, 800 W |

Materials compatible with the SPEEDY series

FLEX

| Grabar | Cut | To mark | |

|---|---|---|---|

| Acrylic | ✔ | ✔ | ✔ |

| Glass | ✔ | ||

| Plastic sheets | ✔ | ✔ | ✔ |

| Leather | ✔ | ✔ | |

| Paper | ✔ | ✔ | ✔ |

| Plastics | ✔ | ✔ | |

| Stone | ✔ | ✔ | |

| Textiles | ✔ | ✔ | |

| Wood | ✔ | ✔ | |

| Metal* | ✔ | ✔ |

CO₂

| Grabar | Cut | To mark | |

|---|---|---|---|

| Acrylic | ✔ | ✔ | |

| Glass | ✔ | ||

| Plastic sheets | ✔ | ✔ | |

| Leather | ✔ | ✔ | |

| Paper | ✔ | ✔ | |

| Plastics | ✔ | ✔ | |

| Stone | ✔ | ||

| Textiles | ✔ | ✔ | |

| Wood | ✔ | ✔ | |

| Metal* |

FIBER

| Grabar | Cut | To mark | |

|---|---|---|---|

| Acrylic | ✔ | ||

| Glass | |||

| Plastic sheets | ✔ | ||

| Leather | |||

| Paper | |||

| Plastics | ✔ | ✔ | |

| Stone | |||

| Textiles | |||

| Wood | ✔ | ||

| Metal* | ✔ | ✔ |

DOWNLOAD FILES

INTERNATIONAL SUCCESS STORIES WITH TROTEC LASER EQUIPMENT

Integrity Laser, USA

Sunshine Barossa, Australia

Eremit Display, Austria

Learn moreThe University of Linz, Austria

Learn moreFrequently Asked Questions about RECORDERS

AND LASER CUTTING MACHINES

What are the advantages of a laser engraving and cutting machine?

The three biggest advantages of a laser engraving and cutting machine compared to other alternative technologies such as milling machines, knife cutting plotters or die cutting presses are: 1. Productivity, i.e. the speed of cutting and engraving processing 2. Shiny edges When cutting acrylic with a laser, preparation and post-processing are not necessary. Contact-free cutting without deformation of textiles, paper or foils.

What is the best laser engraving and cutting machine?

The choice of the right laser engraver depends largely on the area of application. For engraving signs or trophies, the Speedy series laser engravers are also suitable for the production of architectural models or for marking data plates. The SP series laser cutting machines are suitable for large-scale applications in advertising technology.

What is the price of a laser engraving and cutting machine?

The purchase price of a laser engraver can vary depending on its configuration and needs. Costs can vary greatly depending on the work surface and laser power. We will be happy to advise you when choosing the right CO2 laser engraver for product customization.

Is a laser cutting machine the same as a laser engraver?

Laser machines are designed for specific processes: they may be better at cutting or engraving. In principle, a laser engraver and cutting machine can both engrave and cut. However, in detail, there are differences in cutting and engraving speed or in options to further improve cutting or engraving, for example.

How much does a Speedy laser engraving and cutting machine cost?

The purchase price of a Speedy laser equipment depends on its configuration and needs. Costs may vary depending on the work surface and laser power. At CeluPal International we can advise you when choosing the right laser equipment for your needs.

Because customized requirements require personal advice.

LOCATION

ADDRESS

3rd Street 53, Naucalpan Industrial Park, Naucalpan de Juarez

PHONE

52 (55) 2625 2990 / 01 800 000 CEL (2358)E

SCHEDULES

Monday to Friday from 9:00 a.m. to 6:00 p.m.

© 2024 Celupal All Rights Reserved